Greener packaging methods for easier eco friendly fulfilment

Today’s customers are more interested in sourcing those items they can from within their own country simply because of the knowledge of their environment, the pressure to be eco-friendly, and to support their own countries economy. Imports in the UK decreased to £42650 Million in February this year from £43174 Million in January this year and this is partly attributed to UK consumers choosing to “Buy British†Many consumers these days are looking at ways to improve their carbon footprint, and many are looking at everything from the food, clothing, and decorative items they buy to the type of car they drive, and the type of holiday they go on. The rise of the “staycation†is no longer singularly attributed to budget restraints, but many people are choosing to lower their carbon footprint by limiting international travel. 2/3 of UK families stayed in the UK for their holiday in 2013, and this figure is likely to hold up for 2014 too. Protecting the future of the environment has never been more important and consumers are growing more and more eco-conscious.As businesses seek to become more eco-friendly, importing from overseas is often seen as a bad thing. Obviously, we are never going to be able to produce all the goods we need in the UK, so it is imperative that we find the most you can friendly way to move our goods internationally. Therefore, packaging requirements for products need to be carefully investigated, to provide the most cost-effective and eco-friendly form of packaging for each item. From retailers, to logistics providers, the pressure is on to reduce emissions and package more effectively.

So, how can retailers and logistics providers reduce their carbon footprint by looking at packaging requirements?

Currently, retailers are using an excessive level of packaging to ensure that their records are not damaged in transit. This bubble wrap, tissue paper, protective packaging does not only have an effect on a retailers bottom line, it also has an effect on their carbon footprint. Knock-on effect is also taking place on the piece you missed side of things. Always access packaging, if not recycled, you sent to landfill, which is detrimental to the environment. Badly packaged items will also take up far more room on a truck, ship, plane, or pallet than is necessary. Looking at various different methods of packaging will enable any retailer to cut costs on their packaging and also reduce their carbon footprint.There has to be a happy medium. Protecting goods in transit is a significant worry for retailers, as they need to keep customers satisfied whilst keeping costs low, and now with the added pressure on their carbon footprint, they have a whole extra source of worry.

So what should retailers be doing about these issues?

Most importantly, there has to be an element of common sense. Retailers do not have to apply the same principals when shipping pillows as they do with glass picture frames. Those items that do not need to be protected in transit to prevent breakage should be shipped with the least amount of packaging possible, whilst ensuring that their items can be shipped effectively.For example, the pillows: In cellophane in a box is fine. There is no need for bubble wrap, extra fillers or room between the pillow and the box. Pillows have to be one of the least “shipping friendly†items anyway, as their weight to volume ratio means that retailers pay through the nose for space, so if possible, they should be packed tight with very little extra stuffing. Surprisingly, some retailers do not take heed of this advice. I myself recently ordered a set of pillows, which came in a crush proof box, with cellophane and cardboard inserts. Completely unnecessary. These items were not shipped overseas and this is another thing retailers should be aware of. Shipping internationally requires different packaging requirements than shipping inland. A large mailbag should have protected those pillows effectively in transit, and cost effectively too. Luckily, I recycle, so it’s slightly less of an issue, but if I didn’t, and many people still don’t, then that packaging would be going straight to landfill.

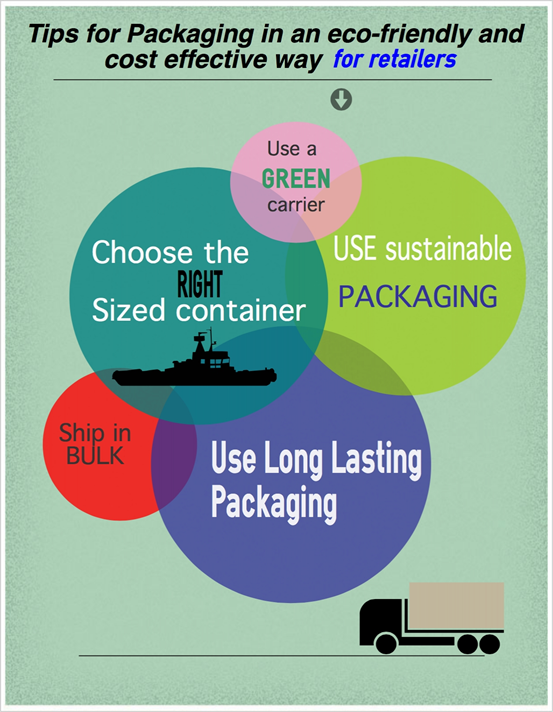

In a nutshell, there are a few pieces of advice to packaging successfully, cost effectively and in an eco friendlier way

Select the perfect size box or container

Sometimes, carriers find themselves restricted by the dimension of boxes they have in stock that they can use to deliver their items. For instance, they could have a product such as a small mechanical piece that is 2 cubic inches, but their nearest sized box is one cubic foot. This corresponds to 1,726 inches of cubic space squandered and extra cardboard in addition to additional product packaging product to keep whatever it is from moving about. The value of having perfectly sized shipping containers in stock is vital for protecting resources and conserving costs.Pick sustainable packaging products

Recycled paper and card for shipping are offered at pretty much the same cost as new products. There is a wealth of offerings, such as cushioning, corrugated boxes, and padded mail bags.The European Union created a measure in 1994 (the Directive on Packaging and Packaging Waste (94/62/EC). This measure was issued to balance various actions taken by many EU nations to effectively increase the incidence of reuse and recycling of packaging. Packaging waste equates to 17 % of Europe’s waste stream, however this number used to be a lot higher.

Take advantage of more long lasting packaging materials

Just as vital as acquiring sustainable packaging materials, is purchasing products that will stand up to wear and tear. From origin to delivery, your standard parcel will get jostled about. If the packaging is not sufficient enough to protect that item, that product will have to be resent, therefore necessitating usage of even more packaging material. For businesses to thrive, their items need to arrive intact at their destination.Another advantage of durable product packaging materials is their capability to be used more than once. A great quality cardboard box can possibly be shipped 5 or 6 times, at which point, duct tape could be placed around the corners and seams to make it last even longer. Therefore, those receiving packages should save the more resilient boxes that come in for reuse by the shipping division.