Mr.

October 21, 2023555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

QTIFfT6g

-1 OR 2+375-375-1=0+0+0+1 --

-1 OR 2+796-796-1=0+0+0+1

-1' OR 2+239-239-1=0+0+0+1 --

-1' OR 2+835-835-1=0+0+0+1 or 'Sygybnje'='

-1" OR 2+307-307-1=0+0+0+1 --

if(now()=sysdate(),sleep(15),0)

0'XOR(if(now()=sysdate(),sleep(15),0))XOR'Z

0"XOR(if(now()=sysdate(),sleep(15),0))XOR"Z

(select(0)from(select(sleep(15)))v)/*'+(select(0)from(select(sleep(15)))v)+'"+(select(0)from(select(sleep(15)))v)+"*/

-1; waitfor delay '0:0:15' --

-1); waitfor delay '0:0:15' --

1 waitfor delay '0:0:15' --

xyTLbeTu'; waitfor delay '0:0:15' --

-5 OR 369=(SELECT 369 FROM PG_SLEEP(15))--

-5) OR 490=(SELECT 490 FROM PG_SLEEP(15))--

-1)) OR 838=(SELECT 838 FROM PG_SLEEP(15))--

ZKpowiA1' OR 158=(SELECT 158 FROM PG_SLEEP(15))--

qta2wDwu') OR 657=(SELECT 657 FROM PG_SLEEP(15))--

I7QH3txo')) OR 175=(SELECT 175 FROM PG_SLEEP(15))--

555*DBMS_PIPE.RECEIVE_MESSAGE(CHR(99)||CHR(99)||CHR(99),15)

555'||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR(98)||CHR(98),15)||'

1'"

1�À§À¢%2527%2522

@@ZffI9

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

DOGsreFz

-1 OR 2+203-203-1=0+0+0+1 --

-1 OR 2+39-39-1=0+0+0+1

-1' OR 2+411-411-1=0+0+0+1 --

-1' OR 2+785-785-1=0+0+0+1 or 'U1108GOK'='

-1" OR 2+178-178-1=0+0+0+1 --

if(now()=sysdate(),sleep(15),0)

0'XOR(if(now()=sysdate(),sleep(15),0))XOR'Z

0"XOR(if(now()=sysdate(),sleep(15),0))XOR"Z

(select(0)from(select(sleep(15)))v)/*'+(select(0)from(select(sleep(15)))v)+'"+(select(0)from(select(sleep(15)))v)+"*/

-1; waitfor delay '0:0:15' --

-1); waitfor delay '0:0:15' --

1 waitfor delay '0:0:15' --

ItfX7VkC'; waitfor delay '0:0:15' --

-5 OR 396=(SELECT 396 FROM PG_SLEEP(15))--

-5) OR 688=(SELECT 688 FROM PG_SLEEP(15))--

-1)) OR 159=(SELECT 159 FROM PG_SLEEP(15))--

KBWVcR0O' OR 344=(SELECT 344 FROM PG_SLEEP(15))--

HX0EazUo') OR 874=(SELECT 874 FROM PG_SLEEP(15))--

lnzAOcdc')) OR 424=(SELECT 424 FROM PG_SLEEP(15))--

555*DBMS_PIPE.RECEIVE_MESSAGE(CHR(99)||CHR(99)||CHR(99),15)

555'||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR(98)||CHR(98),15)||'

1'"

1�À§À¢%2527%2522

@@gnQ49

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555

uyo

a

a

asd

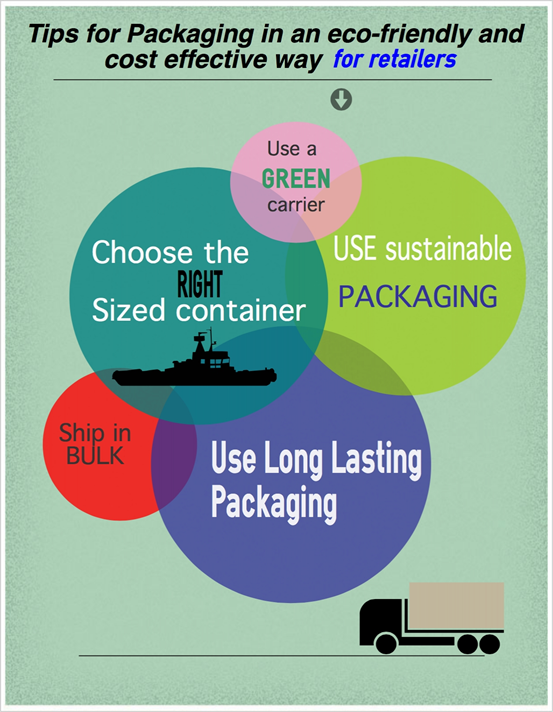

In any typical warehouse, picking and packing are no doubt the most essential activity, and it plays a very great role in customer satisfaction as well as in analyzing the overall supply chain performance. Pick and pack warehousing is part of the entire management system of a supply chain commonly used in product distributions There are various picking and packing plans and one of the best and recommended is the eco-friendly green warehousing plan. It costs nothing more than regular shipping methods but it has more healthy and safe picking and packing solutions. For one to realize a greener and eco-friendly pick & pack warehousing strategy, they should ensure that they:

Nowadays, you’d be hard-pressed to find too many people that don’t

own a smartphone of some kind: almost everyone seems to be carrying an

iPhone, Android or Windows phone. And, on their phone, they’re sure to

have countless apps, from social media to banking, games to emails. And

retail companies are reaping the rewards, too, with dozens of the

country’s biggest names like Asos and John Lewis each with their own app

offering a new way to browse products and make purchases. This article

takes a look at how mobile is one of the best platforms for commerce,

and how you can cash in on it.

Choosing to try new approaches to reaching new customers is a big step

to take: it often involves a great deal of research into that approach

to find out its strengths and weaknesses, to see the true results that

it can give. When it comes to mailing campaigns, that’s no different. A

mailing campaign is a method that quite literally puts your company and

the services it can offer on the doorstep of a potential customer, so

its little wonder that time after time, London businesses see the value

of these types of campaigns. In this post, we take a look at how a

fulfilment company can help you grow your business using a campaign of

this type, and unpack what a mailing campaign entails.

Any good fulfilment company

will do their utmost when transferring goods from one customer to

another. They are aware that first impressions count, and that no matter

how excellent the product is, the memory of how it was delivered will

remain in the psyche of the client long after the product has perished

or died.

As we all know, outsourcing the warehousing and distribution

end of your business can yield fantastic results for your business.

Finding professional logistics services that can take your supply chain

to the next level will only serve to improve your customer service,

keeping your buyers loyal in a marketplace that is becoming increasingly

competitive. In this article, we take a look at some of the dangers

that online businesses large and small face, and the solutions that can

be put into place to combat them.

Providing efficient distribution can often be the deciding factor

between customers that return and those that don’t. Getting fulfilment

right every time is a must for online selling. Follow our golden rules

to online trading and you’ll be making sure those customers buy from you

again and again.

Ecommerce is a very competitive industry, and nine times out of ten a

new customer will pick the least expensive provider of a good or

service, regardless of any other factors. Order fulfilment, and specifically pick and pack

can be responsible for a lot of your overhead, and making efficiency

advances there could help your overall profitability quite a bit.

Every Fulfilment Warehouse

feels the pressure to improve efficiency and service, and to streamline

operations as much as possible. Often when it is time to expand

operations, managers begin to consider bringing in a LMS to help them

keep track of the performance and statistics of larger numbers of

warehouse workers without adding more managers.

Logistics management refers to the process of planning, executing,

controlling efficient, effectual flow and warehousing of goods, services

and associated information from the place of origin to the place of

consumption with an aim of meeting the customer needs. When you let

another person, specialised in logistics offer these services, it is

termed outsourcing logistics.

Omnichannel sales demand an efficient order fulfilment process, and your pick and pack operations

are one of the most important parts to optimise. Making the jump to an

automated pick and pack process can increase the volume each picker can

handle dramatically. No automated system can yet replace all of your

pick and pack workers, but the best can make them much more effective.

The ability to provide an early delivery date is one of the biggest

factors in providing customer satisfaction. In the most recent UPS Pulse

of the Online Shopper survey, fully half of online consumers have

cancelled an order at the ‘shopping cart’ stage if there were no timely

delivery options available or if no solid delivery date was available on

the website. Delivery time is central a factor of customer

satisfaction, and had become the most important ‘deal breaker’ for

online sales. Worse still, 27% of those polled said that a late delivery

was likely to stop them from using that retailer again.

Ecommerce’s popularity and market share continues to grow, and consumers

all over the world have gained an unprecedented degree of comfort with

online and mobile shopping. As they become more willing to explore

alternative online retail options, consumers are turning to ecommerce subscription services (and related automatic renewing services) in greater numbers than ever before.

It is easy to see why – the convenience is huge. Every month, perhaps

every week your staples turn up at your door. For me it’s a bag of

Columbian coffee, a bottle of milk a loaf of bread and a half dozen

eggs. In an earlier generation the grocer’s boy would have delivered the

same riding a bicycle. Another service sends me a different bottle of

wine every month. Perhaps the grocer’s boy wouldn’t have been trusted

with that.

And of course, just about anything that is convenient for shoppers

translates into increased sales for the merchants (online or otherwise)

who support it. If properly managed, ecommerce subscriptions can be more

efficient and less costly from an order fulfilment perspective because

they are regular, repeating events. A good fulfilment partner should be

able to arrange discounted service for regular, reliable ecommerce

subscriptions in high enough volume. It costs them less, so you both

make more money.

The following are a few ways to make ecommerce subscriptions even more effective for you both.

Businesses all over the world are increasingly benefiting from the fantastic services that the courier logistics industry has to offer.

All too many companies select a fulfilment partner without first

ascertaining their abilities with reverse logistics. Reverse logistics

is that part of shipping and logistics services dealing

with the movement of goods back from consumers, usually as a result of

product returns. Not every return is a complete write-off of course, and

a good shipping and logistics service provider should be able to

process returns in such a way as to recapture the maximum value from

them.

The goal of most reverse logistics procedures is to get the returned

goods back into the normal supply stream as quickly as possible, usually

by verifying their good condition and repackaging them at the

fulfilment house so they can be delivered again quickly and

inexpensively.

Supply chain management

applications help you in creating plans and developing strategies for

your business in a more efficient manner. It enables you to assess your

manufacturing capabilities with well thought out logistics by planning

and carrying out the necessary tasks. Profit generation largely relies

on these two aspects because by managing these properly you will

dramatically increase the efficiency. There are a number of links in the

chain in business therefore by missing or not staying on top of one

part this may cause an unnecessary waste of resources.

Supply chain management is a tried and tested method but Enterprise Resource Planning (ERP) has

aided in reducing the inaccuracies and improved the performance of the

supply chain. ERP and Supply Chain Management is a way of planning all

the resources in the business enterprise effectively. The organisations

determine which operating systems and operating performance will assist

them in managing the business operations and meet the objectives of the

business. ERP and SCM also includes the trading partners of the

organisation which are the customers and the suppliers. It is for the

companies who are looking to generate rapid improvement in their

operations. The assessment of ERP and SCM depends a great deal on the

size of the operations and takes about three to four days. The

organisation’s intent, implementation and effectiveness of the existing

operations are assessed based on an ERP model.

Many fulfilment houses now provide admail services, sometimes known as direct mail services or

advertising mail services. That is, essentially, arranging delivery of

adverts or marketing material to existing or potential customers,

usually through the post. All too often dismissed as ‘junk mail’, direct

mail services are one of the most effective and efficient ways to

communicate with your market. Direct mail services are the most common

form of direct marketing, used heavily by businesses small and large,

non-profit organisations and charities all over the world.

As email and electronic communications handle more and more of our

day to day interpersonal communications, the little mail we still get

grows in importance. While we once separated all mail into ‘bills’ ‘junk

mail’ and ‘real mail’, now we see incoming mail as consisting of simply

‘bills’ and ‘not bills’. In fact, the delivery of direct mail

advertising is becoming a large part of the postal service’s business in

many countries, especially the UK and US. As fewer private letters are

sent, post offices around the world are becoming much more welcoming to

direct mail services, and eager to do more business with them.

The Contract Logistics sector

has seen a lot of merger and acquisition activity in the past few

quarters. What information we have from large 3PLs and contract

logistics players indicates that this is likely to continue for at least

the immediate future, and be a major factor in the profitability, or

lack thereof, in the sector as a whole.

Large scale mergers and acquisitions were common before the economic

recession that is just beginning to pass. This time last year, many

would have speculated that as investment money becomes more fluid again,

large scale takeover bids would once again be the norm. However, in the

aftermath of UPS’s failed takeover bid for TNT, consolidation is likely

to continue on a more selective, careful fashion. Smaller organisations

are more likely to be targeted for takeover or merger, especially those

operating in niche industries or peculiar geographic regions.

If you’re a company who needs to reach clients through mailing campaigns, or distributing products then the most feasible way of doing this is by having a mailing house provider. This saves your time, your money and other vital resources. The question is though, what do you look for in a mailing house provider and what are the benefits?

Many manufacturers have taken to outsourcing their packaging tasks these

days, as they find it more cost effective, and it takes away the

headache of dealing with all the issues associated with different

designs, packaging solutions and planning. So how do you know when to

start looking for a packaging solution outside of your own warehouse?

There are many “red flags†that should warn you that you really need to

start looking to outsource, and just a few of them are mentioned below.

Even top-quality cloud-based warehouse management systems have a

measurable lag time when transmitting instructions to your sortation

system. When a warehouse has to act on tens of thousands of tiny

decisions every day, and depend on split second timing for their

efficiency edge, even a small delay can make the whole system somewhat

ineffective.

Most experts agree that there is a definite need for warehouse control systems

(WCSs) and warehouse management systems (WMSs). The fulfillment

industry has experienced a great deal of change recently, and expects to

see as much or more in the years to come. The ecommerce and omni

channel distribution movements have made the supply chain substantially

more complicated, and the IT industry has responded by providing

solutions that can act on these new levels. Simple ‘pick pack post’ fulfilment would not be simple at all without these modern control and management systems.

Still, they are not without their problems. Many of these have more to

do with the way these systems are implemented than with the systems

themselves. Some experts feel that too many distribution centre or

warehouse managers have adopted cloud solutions too quickly, rather than

choosing a more traditional warehouse management system, installed on

their own, local servers.

At the moment, most users of cloud-bases WMSs are smaller warehouses

with basic equipment, often little more than lift trucks, handheld

barcode scanners or RFID devices.

Cloud-based solutions are appealing because of their lower up-front

costs. Upgrades and maintenance are also avoided, at least as separate

expenses, as that is all part of the SaaS package.

One of the biggest expenditures for those who retail online is their

shipping and fulfilment. There are many costs involved before the

product reaches the customer and every part of the procedure needs to be

done well to ensure a successful transaction; crucial for success. Bad

fulfilment, poor order processing and delayed deliveries can make your

customers extremely unhappy and eliminate the chance of more business

and good word of mouth. So, ensuring that you get your items delivered

in a speedy fashion needs to be the top priority in a marketing

strategy. The major online retailers such as Amazon and eBay have their order processing and fulfilment needs down to a fine art and this greatly contributes to their huge popularity and massive success.

By streamlining your company’s operations through a pick and pack despatch partner,

this can greatly improve your fulfilment procedures as well as saving a

significant amount of money in import and export fees, and eliminate

security headaches. Order fulfilment can be a real headache, a drain on

time resources and a crucial thing to get absolutely right; by hiring

someone to do this for you this can lead to effective gains in consumer

satisfaction which, when it boils down to it, is how a company stays

afloat in the current climate.

‘Order processing’

is actually a very broad term, used to refer to all of the processes

followed to fulfil any order placed by a consumer for a good or service,

including picking, packing, and transporting the package to a shipper

for delivery. It is the heart of order fulfilment, and usually takes

place in a distribution centre.

Order

processing starts when an order is taken from a customer. More and

more, these orders are taken online, but telephone and written orders

are still a part of the process. Order processing ends when the customer

actually receives the products, and accepted that the delivery is

complete, accurate and satisfactory. As you might guess, the complicated

parts are between those points, and can vary dramatically between

different distribution centres and between different goods or services.

It seems everyone has a smartphone or a tablet these days, and they

are being used for more and more of our daily computing tasks.

M-commerce sales have more or less doubled since this time last year,

and makes up a substantial portion of total online sales. The experts

all agree that e-commerce over mobile devices will continue to take up a

larger and larger share of the market, though there is spirited

disagreement about the predicted rates of growth.

This means that many of your website visitors are already viewing it

on a three to seven inch screen, whether your site can recognise and

adapt to this fact or not. If you aren’t providing a good user

experience for such a large segment of your visitors, is it surprising

that they are turning to competitors who are?

Any merchant, whether e-commerce, catalogue, or hybrid brink-and-mortar, will tell you that order fulfilment is vital to your customer experience,

and much more important to the all-important return business than front

end design, search engine optimisation or even advertising. The prompt

delivery of a customer’s order, as well as the accuracy, condition and

appearance of the order, is what customers will remember about an

internet purchase, long after they’ve forgotten everything else. The quality of order fulfilment is therefore more important to the development of your brand than almost anything else.

In the same way, your pick and pack operations are the beating heart

of your fulfilment processes. If you aren’t quite ready to turn your pick and pack or order fulfilment processes over to a specialist third party logistics partner,

consider these four strategies to make your pick and pack processes all

that they can be, improving the accuracy, efficiency, and speed of your

entire order fulfilment operation.

Not long ago, Branding Brand made its worldwide Mobile Commerce Index report for April 2014 public, and the results were bullish on m-commerce. The report consolidated global data on consumer activity that came to ecommerce retailers through smartphones and similar small mobile devices, and gave us some useful comparisons of the performance of smartphone-optimised ecommerce sites between April 2013 and April 2014.

Integrated Logistics Support (ILS)

is a technical process in which support and logistics considerations

are integrated within the design life cycle of a product or system. The

overall aim is a cost-effective and durable system that performs to its

maximum capabilities.

A lean, functional system that requires minimal support thereby

increasing one’s return on investment (ROI): functional, reliable and

usable whilst conforming to standards of best practice.

ILS is popular with product support, e.g. distribution and customer service systems.

As we near the midpoint of the decade, the new consumer landscape of the ‘teens’ is now well established. Two substantial changes from the 2000s have already become clear.

Though many experts predicted that cloud computing would be the development that brought modern supply chain execution software solutions (SCEs) such as warehouse management systems (WMSs) within the reach of the small or medium warehouses that could not afford the initial adoption costs for these products, they have been very slow to arrive, and even slower to be adopted. Cloud based WMS options have been available for years, but have accounted for only a tiny fraction of the UK WMS market in 2013. To put that in perspective, cloud based CRM software accounts for nearly half of that market now, and the supply chain management sector looked at a s a whole is more than 20% cloud based.

There are many benefits to outsourcing your pick and pack services, but none greater than the savings on the resources of time and money. You will save much time by no longer attempting to pack and fulfil all orders alone, and you’ll save money by finding a provider who will over special rates such as loyalty schemes or discounts. A more secondary factor, although still important is the customer satisfaction you can gain without doing any of the work to achieve this – by finding a supplier with a reputable company and whose active years and client list are extensive, you are guaranteed a speedy and successful service which in turn means that your customer will receive their goods at a quick pace, every time.

Fairway has strengthened its Medical Fulfilment offering by extending

its existing MHRA Wholesale Dealer’s Licence to also include Veterinary

Products. This addition was to meet the needs of a specific customer and

involved a detailed external audit by the MHRA of Fairway’s security,

processes, cleanliness and staff training. This demonstrates the

company’s commitment to continue to expand its service offering to

customers.

Ecommerce retailers succeed or fail based on their web presence. Your

entire business rides on these bits of code, so shouldn’t you make sure

you’re using every trick in the book to its best potential? We’ve

included a few words of advice on some of the things even

well-established website can often improve on. After all, the more

sales you make, the more fulfilment business we do.

It is easy to fall into the mode of thinking that your core values

need to be quality and service, and that your website need only be

functional and efficient. This is only partially true, though. Letting

quality or service slide will end an ecommerce concern in a hurry, no

doubt about it, but a lacklustre or an unpleasant website can doom an

otherwise excellent business to obscurity and failure just as quickly.

Your online customers will probably never meet you or speak to you,

so you have to put your charisma and passion for your products into the

website itself.

Supply chain management is complicated for a few different reasons, but one of the most important is the relatively high rate of turnover within it. The responsibility of managing a supply chain is more likely to be passed between different individuals in the same organisation, or increasingly made the responsibility of a 3PL, than many other business functions. This can mean that a new manager is handed the reins with little understanding of his or her predecessor’s strategy or aims.

Many ecommerce retailers understand the concept of inventory carrying cost (ICC) in the abstract, but have trouble applying it operationally. Many e-tailers do not give proper weight to the costs of carrying inventory, and therefore miss a lot of essential inefficiencies in their operations. I want to highlight a few points on how ICC affects inventory and how understanding your real ICC is vital to reducing inventory while maintaining flow-through. Fairway Fulfilment & Logistics explain ICC in more detail below.

Fulfilment is not just defined as the process of receiving an order for a product and making the necessary preparations to get that order ready for delivery to the customer. There is a great deal going on in the middle of that statement: picking the product from the warehouse shelf; packing it into a suitable box to ensure that it arrives intact and undamaged; printing out a delivery label with name, full address and delivery instructions and company sorting code. All of this goes on before the delivery driver handles the package and ultimately hands it over to the customer.

Machine to machine data flow (M2M), once called embedded computing

and now ‘the internet of things’ (IoT) is gaining ever larger shares of

the market.

The order fulfilment and e-commerce sector caters to new market participants more than almost any other, so we get a lot of questions about how fulfilment and e-fulfilment actually works. We have gotten a lot of questions lately about minimum order volumes, fees, and storage levels and how they work in the third party fulfilment market, and I will try to answer some of those today.

Ecommerce is changing what shopping means to people all around the world, but unfortunately it is also changing the way a small but growing minority of customers try to steal merchandise. Smaller e-commerce sellers in particular may be vulnerable to this, and should work closely with their logistics partners to prevent it.

Omni-channel or multi-channel fulfilment has significantly become the standard for retail providers, manufacturers and merchants to fulfill a broad wealth of different shipments. For that reason, operations now have to be more versatile and efficient to ensure the increasing range of order types and sizes are fulfilled, by showcasing order fulfilment processes with highly intelligent automation of the process.

Every business, or professional seller, will scrutinize their

incomings and outgoings to create a greater profit margin. High profits

with low expenditures are what keep a business productive and running

well, so business owners explore every avenue where they could cut

costs. This is apparent with packaging for items which are to be shipped;

by saving on packaging there will be a smaller outlay with the same

return on product price. You can do this by choosing your packaging

wisely, with much research and thought and looking into things such as:

The e-commerce market is expanding rapidly in the UK (as in the rest of the world), and online customers are demanding express delivery much more often that has previously been the case.

Private courier companies have grown almost exponentially recently, and the parcel boom is directly tied to the number of e-tail and e-commerce businesses now operating in the UK.

In fact, 2013 saw 1.83 billion packages sent via courier from the UK

(and most delivered within the UK). There are just under 64,000,000

people in the UK, and that means that every man, woman and child in the

UK got 29 packages last year on average. 2014 is set to be an even

bigger year for ecommerce, seeing more than 2 billion packages, and more

than £7 billion worth of business to the courier industry.

3PLs (third party logistics partners) have been a vital part of the supply chain for years, but the role they play in the supply chain continues to shift as economic conditions change. They now handle everything from raw materials to finished products, packaging, and order fulfilment. Experts tell us that the evolving business models of these 3PLs are a major force behind the growth expected for the consumer products industry in coming years.

E-commerce can be a very rewarding, efficient way to do business, but you have to organise properly if you want to get ahead. Most ‘e-tailers’ or ecommerce sellers prefer to begin with the help of an experienced warehousing, distribution and fulfilment partner who can handle the whole ‘back end’ of the operation, while the merchant focuses on business and sales, maintaining the website, and any other sales channels that they have developed.

Customer experience is your number one priority as an ecommerce

seller. You have a lot of competition, and your customers can probably

get essentially the same product from quite a few other sellers. Once

they have spent money with you, they are more likely to go through you

again, but only if they receive the level of customer service they

demand.

Time is your most valuable commodity. It is just about the only thing you cannot buy. How you spend your time determines your productivity and, ultimately, your business’ profitability.

Small online businesses and e-commerce start-ups have their own unique set of needs in terms of order fulfilment. Order volume may be very low for a time. It will almost certainly be inconsistent, at least at first. Small concerns cannot handle high setup costs, large monthly retainers or fees, or minimum order requirements. It just isn’t practical at that scale.

Whilst choosing the right fulfilment, distribution, and supply chain management partner may be the most important step to success as an e-tailer, there are quite a few things you can do to make life in e-commerce easier on your end as well.

SMI (Slow Moving Inventory) is, of course, a relative term, and one

business’ SMI can move a lot faster than another’s A list. Building a

definition specific to your operation is the key to dealing with SMI

appropriately.

This is a particular concern for ecommerce retailers, as many of them use e-fulfilment services and may not be aware of the speed some of their SKUs move.

We’ve all heard about omni-channel marketing (wasn’t it just

multi-channel last month?), and how it is supposed to be the next big

thing. Most of us have decided that this time it’s not all hype, and we

should brace ourselves for the inevitable changes in the industry.

That is exactly the wrong kind of thinking. When a big change comes to any sector, there are three types of responses.

Not long ago, e-fulfilment was exclusive to retail operations. Now, though, a number of B2B and wholesale businesses are edging into the ecommerce fulfilment market. Historically, B2B operations of any kind have not been as focused on good customer experience as retail (or etail) operations, and fulfilment was seen as unimportant to the customer experience, unless and until something goes wrong.

Early point of sale (POS) management used to simply be a case of entering a few numbers into an oversized calculator, waiting for the ping! and

making sure you handed the customer the right change. Nowadays,

customers find the sight of a traditional cash register an antiquated

quirk; a relic from the Museum of Retail Experiences.

When POS systems that used barcodes and scanners were introduced to

shop fronts across the retail industry, they quickly became an

established tool for automatically recording sales and stock levels, as

well as customer loyalty schemes and discounts. As retail sales grew, so

did the need for bigger and better POS management software.

Lawrence (real name withheld, he’s not ready for the kind of instant

fame that comes from being mentioned on our blog) runs a custom clothing

silk-screening and printing business.

A few years ago Lawrence discovered the internet in a big way, and

customers from all over England have discovered him. The problem is,

Lawrence wasn’t really ready to expand as much as he has, recently. The

move from doing business on a walk-in basis from his shop to printing

and shipping hundreds of garments a week trough eBay and his own website

has led to 12 hour days and a shop, and apartment, completely full of

inventory.

“I couldn’t even have friends over – my outbound orders were piled up on my couch.â€

It takes a lot of trust to let an outside company manage and perform some of your most vital business functions. Fulfilment is one of the most vital points in your logistics chain. Getting it right can make things very easy for you, but choosing the wrong partner could put the nails in your coffin.

As order fulfilment is one of the most important parts of any

business, it is essential that it’s done properly, which often means

investing a lot of money into setting up an efficient supply chain,

particularly if you’re just starting out.

If you’ve chosen to partner up with a fulfilment centre then you

won’t have to worry about the big decisions regarding your order

fulfilment – the professionals will take care of all that and it will

usually cost less than if you were taking it all on yourself.

But whether you’re outsourcing all or just part of your fulfilment needs, it’s still possible to lower your overheads even further with a few simple changes on your end:

When helping an e-fulfilment client put their house in order, some of the most frequent problems are with SKUs. All too often, the merchant has only a handful of inflexible SKUs, or an unmanageable array of to-small units. A good rule of thumb is that you should have fewer SKUs than the number of orders you despatch each month, but this can vary greatly by industry and product type.

When it comes to order fulfilment, it’s no surprise you want the best service available. A successful fulfilment company equals

a successful supply chain and there are many companies out there

promising the world, especially when it comes to the final part of the

process: distribution.

Some fulfilment companies split their courier services between third

party distributors, while others manage distribution in-house. But how

can a fulfilment company with an on-site courier service improve the

overall effectiveness of your supply chain?

This year is set to be busy for the logistics industry and as your company grows, you’ll need more time to invest in other areas of your business. Outsourcing your fulfilment to a specialist e-commerce or order fulfilment service can take away the stress of delivering products and free up your time to expand your business.

A successful fulfilment service means satisfied customers. From the moment they add an item to their shopping basket to the point they unwrap their product, the whole process counts. So we’ve outlined three of the most essential elements of order fulfilment to ensure a successful service.

A study of major world industrial markets by Jones Lang LaSalle shows

that on average, there have been four consecutive years of industrial

growth. 2013 represents a 5 year high of world industrial output, and

all indicators predict further expansion in 2014. As a result, warehouse

space utilisation has been growing as well, and distribution and

fulfilment houses have been expanding.

Expansion in 2014 so far has been driven by growing demand for ecommerce fulfilment

and the resulting need for large amounts of sophisticated warehouse

space. As a result, 2014 is set to be ‘the year of e-fulfilment’. The

coming year should see a growing demand for distribution centres with a

robust e-fulfilment infrastructure near large population centres.

However, some supply chain managers are bucking the trend. Smaller,

more specialised warehousing space is in high demand amongst very

responsive, agile shippers. The key feature for such space seems to be

that the space be accessible to fluid distribution channels.

When a customer has a complaint, where do they turn? In a bricks and

mortar store it’s normally straight back to the counter or to a

designated customer service till. If that’s not possible, a customer can

telephone a company’s customer care line, where staff are trained in

the art of customer response handling.

Large global corporate companies often invest heavily in their

customer response handling as this is the point where a customer could

be lost forever. Small to mid-sized companies might not have the

financial resources to dedicate to customer response handling and so

there is added pressure to get it right first time.

Starting your own business is an exhilarating feeling. You’ve taken a

single idea and turned it into a reality, whether it’s selling unique

handmade products from home or discovering a gap in the market that

desperately needed to be filled.

When that business is up and running, you’ll no doubt be involved in

every single part of its day-to-day operations, micro-managing every

little detail to make sure things run as smoothly as possible,

especially where order fulfilment—actually getting the product to your

customers—is concerned.

Order fulfilment tends to be one of the most expensive parts of any business, but it needn’t be.

With e-commerce quickly taking over the high street as the world’s

preferred method of retail therapy, there’s never been a better time for

online businesses to reach wider audiences and strengthen their

customer base.

However, if you’re a retailer who established their brand on the

e-commerce scene a long time ago, but find yourself losing customers

instead of gaining them, you need to re-evaluate your business model and

find the causes behind the slump.

There will always be fluctuations in sales during certain times of

the year, whether you are purely an online retailer, a bricks and mortar

store, or a combination of the two – but a downward trajectory can mean

that something is amiss.

Everything might seem perfectly fine on the surface: your website is

attracting plenty of traffic and your online shop front is appealing. In

any business, this is the customer facing part of your brand, a

reflection of both your company and the management behind it.

Modern customers expect more from online commercial businesses –

fast, efficient delivery and products that arrive in excellent

condition.

But behind the scenes there could be a very different story going on,

particularly when it comes to your fulfilment services. If you handle

all your own fulfilment in-house, there is added pressure to maintain an

effective supply chain as well as keeping up with all the other aspects

of running a company.

If you outsource to a poorly managed or in-experienced fulfilment

house that provides your customers with shoddy customer service, poor

delivery and unnecessary costs, your brand is being negatively affected

without you even realising.

Promising your customers the best is one thing, but if you’re

struggling to keep up with demand on your own, you should seriously

think about enlisting the help of a professional and experienced fulfilment company, otherwise you’ll be hit with bad customer reviews and requests for refunds.

If you want to build your customer base back up to the same levels

you enjoyed when you were at your peak, then providing exceptional

e-fulfilment is one of the best ways to go about it.

Finding the right fulfilment partner can save you time and allow you to focus on the core aspects of your business. It allows you to grow your business without the expense of upgrading or expanding your facilities. Because a fulfilment company will do a high volume of orders, they can take advantage of the economy of scale to reduce your overall costs. They are also flexible enough to adapt to seasonal order fluctuations, and to add new lines easily. They also have the ability to become warehousing and fulfilment experts. This is Fairway Fulfilment & Logistics core business, and we have become very good at it. In the end, you’ll benefit from more efficient operations and happier customers.

Running a pick and pack service is all about ensuring the fulfilment of goods and products. On the surface, a successful pick and pack company is organised, reliable and timely. However, a lot of effort goes in behind the scenes of a successful pick and pack service and very often it’s the attention to detail that sets one service provider apart from another.

For many industries, 2014 is shaping up to be a busy year. Planning for an increase in activity will ensure that your order fulfilment service runs like clockwork and is able to meet demand. Here are our top tips to ensure your order fulfilment service operates smoothly.

Supply chain collaboration can be beneficial for every company

involved. Companies that work together to offer supply chain solutions

often see dramatic reductions in fulfilment time, inventories and costs,

as well as seeing improvements in customer satisfaction and service

levels.

Focusing on Strengths

Companies who work collaboratively often do so in the wrong way,

using collaboration as a means of filling voids in their own individual

capabilities. The most successful providers of supply chain solutions

focus on strengths and use them to their advantage rather than

compensating for weaknesses. By identifying what each company in the

supply chain does well, collaboration becomes easier and more effective

for everyone involved.

If you’re struggling to use shop-ready websites that offer limited

control, an effective POS management system can radically improve the

way you run the ecommerce side of your business.

One of the best parts about being the owner of a small business is

that you’re the boss – it’s you who gets to make the rules and oversee

everything, including one of the most important elements: order fulfilment.

If you’re the proud owner of a small business, then you’ll already

know the value of maintaining a smooth fulfilment operation, and will

have probably noticed the hundreds of companies trying to get your

attention by promising the best fulfilment service possible.

Love is in the air and so are sales of premium red roses, luxury

heart shaped chocolate boxes and a number of other Valentines Day

products. The majority of these orders will be purchased online and

delivered straight to the intended recipient, with no direct contact

between the customer who purchased the item and the product itself.

With big calendar events like Valentine’s Day, customers like to show

that they’ve put a lot of effort into their gifts. With a gap between

the buyer and the product, fulfilment companies can provide those little

extra touches using professional hand finishing and enclosing teams.

This is also a very lucrative part of seasonal fulfilment as you can

charge a small fee for professional gift wrapping and customers are more

than happy to pay for the service.

Supply chain management encompasses every part of the flow of goods from point A to point B, including sourcing raw materials, liaising with manufacturers and overseeing the complex chain of networks that make up the global supply chain.

Ecommerce is rapidly becoming the number one way to sell products, cutting out the need for costly ‘shop fronts’ and all the expenses that come with them.

When you start your search for the right fulfilment house to cover

your ecommerce business, the first question on your lips is probably

going to be “how much will it cost me?â€

Every fulfilment company will be different; most will offer a basic

ecommerce fulfilment service that will cover all the essentials

(distribution, pick and packing, handling etc) but there will be slight

differences depending on the size of the company, their experience and

other details.

Below is a brief guide to some of the service fees that you are likely to find on your fulfilment bill:

If you’re still feeling a little shell shocked after the run up to Christmas 2013 then now is the time to take a step back and reassess the state of your fulfilment house. With most of the post-Christmas January sales out of the way, it is the perfect time to fix any problems that occurred during or just after the Christmas rush.

Last week we looked at Network infrastructure strategies that support

same day delivery. This week we look at ways to manage personnel

towards the same goal.

There are three main types of transportation in the fulfilment

industry that will get your goods where they need to go, or enable them

to be imported from other countries: vehicle, shipping and air freight.

Although transporting goods via shipping is arguably the most popular

way to move goods internationally, and road vehicles preferred where

local delivery is concerned, air freight has distinct advantages in the

overall speed of international delivery, as well as short haul local

flights that cover large distances in a matter of hours.

Fulfilment houses that have been strategically placed next to major

airports are often sold to clients on their ability to transport goods

faster due to the proximity of air freight services.

Unrivalled online retailer Amazon.com recently obtained a patent for “anticipatory shipping†and announced its plans to launch a system that, if successful, would dramatically shorten its customer order fulfilment.

Today, I’d like to share with you a case study of a young woman who would not be where she is today without a quality fulfilment partner for her home business. Her name has been changed for the sake of privacy, but let’s call her Lily.

She felt like she was missing out on her children’s lives at her 9 to

5, so she left her job in the banking industry to sell toys from home.

At the time, her daughter was only five, and her love for both

traditional and educational games inspired her mum.

Lily started a small online store to sell high quality children’s

games, at first just to her friends and neighbours, but eventually to a

growing clientele. “I always used my daughter to choose the products,

and my customers were always happy with her choices.â€

“I only wanted to have the freedom to pick my daughter up from school. I never knew the business could become so successful.â€

Several years on, Lily has launched her toy shop on a major online

facility’s site, and she needed a dedicated fulfilment house to handle

the much greater volume of business she was suddenly doing.

“For the first time in what feels like years, I have time for the

things that matter to me, and to grow my business as well. I’d never go

back to the old way of doing things.â€

With her fulfilment partner handling all the warehousing and order

processing, Lily’s business was finally not crowding her out of her own

home. As a toy store, she did fully half her sales leading up to

Christmas. “By November, we could barely move for the stock we had to

keep in the officeâ€. Better still, the increased capacity lets her make

enough sales to improve her lifestyle substantially. Lily says that her

success is nothing compared to the joy she has being a full time mum on a

full time businesswoman’s salary.

Last week we looked at ways to manage your inventory to achieve the

current holy grail of fulfilment, same day delivery. This week we will

examine network infrastructure, and how you can get everything where it

needs to go in time.

There are two basic strategies you can follow, depending on the 3V

analysis in the last installment. If you have a high 3V product, you can

use a single warehouse model. This makes your logistics and supply

chain simpler than the multiple-warehouse option, but requires you to

commit to somewhat expensive freight options to your more distant

customers. This model only really works well if your customers are

clustered in major cities which are in the same general area. Again,

luckily for England the bulk of most nationwide business’ customers are

in the South, or close to it. The freight expense will generally be

lower than the cost of the extra warehouses or fulfilment partners, as well.

With large international companies like Amazon experimenting with same day delivery, merchants and fulfilment companies need to cooperate to compete.

First things first: to get a product delivered on the same day it is

ordered, the product has to be in stock and within an 8 hour journey of

its destination. England is in a better position than may countries, as

even a good bit of Scotland is an 8 hour lorry ride from the London, and

fully 1/3 of the population is clustered in the Southeast alone.

Companies pioneering this strategy in the US or mainland Europe have to

stock a lot of extra inventory along a network of warehouses, making it

much more expensive.

In the industry of order fulfilment services, response handling is the term for any reply or action taken when a customer responds to materials provided by your business. Fulfilment houses often provide this as an extra support service alongside standard fulfilment jobs such as pick and pack, storage and distribution.

If you’ve not already made the jump from the traditional high street

retail shops to online ecommerce, then you’re already trailing behind

the vast number of established retailers and new start-ups that are

benefitting from this change.

Ecommerce is growing every year as more and more people change their

shopping habits, buying everything from luxury goods to everyday

essentials online.

Technology has played a big part in the success of ecommerce – the

very nature of its platform, the ever expanding internet, has given

retailers the freedom and flexibility to maximise their profits by

building on their brand in a completely virtual setting.

In the fulfilment industry,

picking and packing items before they are distributed to customers is a

large and often complex procedure. This is especially true when certain

products or materials can’t be fully packaged by automated machinery

and require hand finishing and enclosing.

Though a particular product might need a little more hands on care

before being distributed to customers, in the case of marketing, hand finishing can actually help your brand reach a greater number of people.

Not only that, but with such massive volumes of different products

requiring hand finishing and enclosing every day, it’s a vital part of

the fulfilment industry and one that can effectively boost sales, brand image and positive customer feedback.

With a combination of automatic machinery and trained hand finishing

staff, orders reaching into the thousands can be completed and

distributed within a matter of days. Some examples of how this might

benefit your business include:

The point of sale, or POS, is the moment your

customer completes their purchase of a product. In a bricks-and-mortar

store, this would be at the till. Online, it’s would be the point where

the customer clicks on the ‘confirm order’ button.

Consumers are switching to online purchases for almost every

essential and non-essential purchases in their lives; they can do the

grocery shopping from the comfort of their own homes, order that

complete DVD box set they’ve been after for months, or even finish all

their Christmas shopping on time and in one sitting.

What is it that first attracts new clients to a fulfilment house? A recommendation via word of mouth from another business owner? A snazzy website loaded with pictures, testimonials and blogs? Or perhaps a bit of both? Although recommendations and a professional appearance are important, a new client will sift through the available fulfilment houses and ultimately choose the one that provides the order fulfilment services they need.

As we get stuck into January and deal with the increasingly unstable

weather sweeping the nation, many personal New Year’s resolutions will

have been made, and some even kept, with plenty more that didn’t quite

make it past the third day.

In the fulfilment industry, the New Year can be a

great time to take a fresh look at the industry as a whole and stir up

new ideas and solutions for a rapidly changing environment.

For business owners, it could potentially be the start of their

company’s expansion into new territories, grabbing the attention of new

customers and maintaining their relationship with regulars.

For 2014, instead of a personal one, why not make a business

resolution that you can stick too, like aiming to make this the year

that your get your e-commerce up and running, or creating and implementing an effective marketing campaign to encourage new customers?

Rewarding consumer loyalty is one of the simplest

and most effective ways to imprint your brand on the minds of your

customers. They often feel that their loyalty is appreciated and are more likely to purchase something from you in the future.

From collecting points that customers can update and manage online to

free gifts or bespoke promotional merchandising, having a rewards and

loyalty scheme in place can massively increase brand awareness and

encourage customer loyalty.

Some order fulfilment companies

deal directly in the procurement and delivery of non-monetary rewards

and loyalty gifts, while others may treat your loyalty stock as simply

another product to be distributed.

Hand finishing and enclosing is a fairly self explanatory process in the fulfilment industry,

even if it isn’t always a simple operation. Bespoke packaging for

physical products or marketing campaigns that are too delicate or

complicated to be machine packaged are finished off by hand and

delivered directly to your customers.

It is a fantastic way to reach your customer base and encourage general interest. While hand finishing and enclosing

is used mainly for distributing promotional material to your end users,

it can also provide unique and even fun extras that will really

surprise your customers.

Promotional materials such as personalised letters or vouchers for

money off future purchases targeted directly at one time or regular

customers can in fact push sales – and profits – through the roof, while

an effective marketing campaign targeted at new customers (think free

samples) can increase brand awareness.

One of the biggest customer complaints regarding deliveries of large

items is waiting in all day for delivery. There are cases where the item

in question fails to show up at the specified time or day. This can

infuriate customers who will have no doubt had to rearrange their

schedules in order to receive the items.

All over the internet there are comments and angry customer reviews

about having to take a half or sometimes even the whole day off work,

sending out ripples of disruption into other areas of the customer’s

life.

Recently there have been more and more companies, particularly from

some of the biggest names like The Royal Mail, who have extended their

delivery hours into the evening, from 6pm onwards, in order to cater for

people who work during the day. Fairway Fulfilment & Logistics can assist your business with ensuring customers receive their goods on time, call us today on 01753 588469 for more information.